The Future of Automotive Coatings: Automatic Painting Machines

In today’s rapidly evolving automotive industry, the demand for efficiency and quality is at an all-time high. Among the innovations driving this change are automatic painting machines. These machines are not just tools; they represent a fundamental shift in how vehicles are painted, enhancing productivity and ensuring impeccable results. In this extensive article, we will delve into the world of automatic painting machines, exploring their advantages, technology, and impact on both the automotive and paint & sip industries.

Understanding Automatic Painting Machines

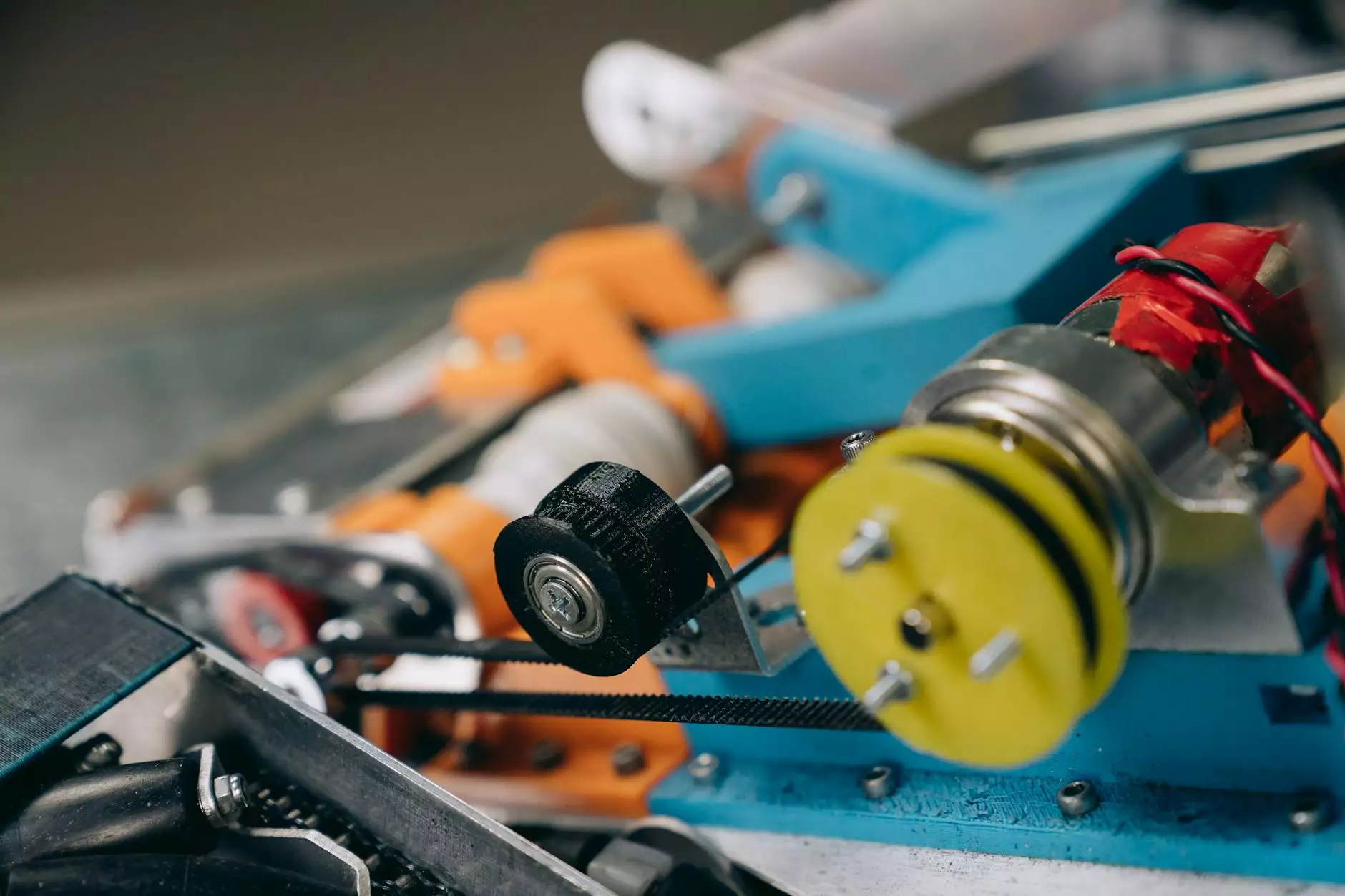

Automatic painting machines are sophisticated pieces of equipment designed to apply paint to vehicles with minimal human intervention. They utilize advanced technologies and robotics to provide consistent and high-quality finishes. These machines can operate in various environments, from large-scale manufacturing plants to smaller automotive workshops.

How Automatic Painting Machines Work

At their core, automatic painting machines incorporate several critical technologies:

- Robotics: Robotic arms equipped with painting guns provide precision in application, ensuring every part of the vehicle receives a uniform coat.

- HVLP and Electrostatic Spray Systems: High-Volume Low-Pressure (HVLP) technology reduces overspray and paint waste, while electrostatic systems enhance adhesion, ensuring optimal coverage.

- Computer Vision: Many modern machines employ computer vision systems that allow them to detect surfaces and adjust the spray patterns accordingly for even better results.

- Automated Conveyor Systems: These systems transport vehicles seamlessly through the painting process, increasing the speed of production while reducing labor costs.

Advantages of Automatic Painting Machines

The integration of automatic painting machines in the automotive industry brings forth a plethora of advantages:

1. Enhanced Quality Control

With precision engineering, automatic painting machines ensure that every vehicle is painted uniformly without the inconsistencies that can arise from manual painting. This leads to:

- Uniform Coating: Consistent thickness of paint across all surfaces.

- Reduced Defects: Lower chances of drips, runs, and uneven finishes.

2. Increased Productivity

Time is money in the automotive industry. Automatic painting machines significantly boost productivity by:

- Speed: Machines can complete painting tasks much faster than manual labor.

- 24/7 Operation: They can operate continuously, reducing production downtime.

3. Cost Efficiency

Investing in automatic painting machines can lead to substantial cost savings over time:

- Reduced Labor Costs: Less need for skilled labor.

- Lower Material Waste: Improved application techniques lead to decreased paint consumption.

4. Enhanced Safety Measures

By utilizing automatic machines, human exposure to harmful paint substances can be minimized. This fosters a safer working environment as:

- Less Human Interaction: Robots handle the hazardous materials, reducing health risks for workers.

- Improved Ventilation: Systems can be properly integrated with ventilation technologies to manage fumes.

Challenges in Implementing Automatic Painting Machines

While the benefits are clear, there are also challenges that businesses must consider when integrating automatic painting machines:

1. High Initial Investment

The initial cost of purchasing and installing automatic painting machines can be substantial. However, businesses should weigh this against long-term savings.

2. Training and Maintenance

Employees require training to operate and maintain these machines. Establishing a comprehensive training program is essential for maximizing the technology's potential.

3. Space Requirements

Automatic painting machines can occupy a significant amount of space. Businesses must plan their factory layout accordingly to accommodate these machines effectively.

Innovation in the Paint & Sip Industry

The advancements in automatic painting machine technology have also made waves in the paint & sip industry, a flourishing sector that combines creativity with social interaction. Here’s how:

1. Streamlined Production for Customized Paint Products

Companies are leveraging automatic painting machines to create customized paint products efficiently. These machines allow for:

- Personalization: Enabling customers to customize colors or finishes.

- Faster Turnaround: Ensuring quick processing for high-demand products.

2. Pop-Up Workshops and Community Events

In the paint & sip scene, automatic painting machines can enhance events by providing participants hands-on experience with the technology. These workshops are popular for:

- Education: Attendees learn about advanced painting techniques.

- Fun: Participants enjoy a creative experience using high-tech equipment.

Future Trends in Automatic Painting Machine Technology

The future of automatic painting machines is bright, driven by innovation and the quest for excellence in the automotive sector. Here are some predicted trends:

1. Increased Use of AI and Machine Learning

Artificial Intelligence (AI) is set to play a pivotal role in optimizing painting processes. AI can help to:

- Predict Failures: Analyzing data to foresee and prevent potential breakdowns.

- Adjust Techniques: Learning from previous applications to enhance the quality of future applications.

2. Eco-Friendly Practices

As sustainability becomes more important, automatic painting machines are expected to adopt eco-friendly practices, including:

- Lower VOC Emissions: Utilizing paints that emit fewer volatile organic compounds.

- Recyclable Materials: Incorporating recyclable components in machines and processes.

3. Integration with IoT

The Internet of Things (IoT) will enable automatic painting machines to connect and communicate, leading to:

- Real-Time Monitoring: Keeping track of machine performance and efficiency.

- Remote Access: Allowing technicians to troubleshoot and manage machines from anywhere.

Conclusion

Automatic painting machines stand at the forefront of innovation in the automotive and paint & sip industries. Their ability to enhance quality, increase productivity, and ensure safety cannot be overstated. As technology continues to evolve, we can expect even greater advancements that will shape the future of painting processes. By understanding the potential and challenges of these machines, businesses can make informed decisions that not only benefit their operations but also contribute positively to the environment.

For automotive companies and paint & sip businesses alike, embracing the possibilities presented by automatic painting machines will remain a pivotal aspect of staying competitive in an ever-changing landscape. The combination of technology, creativity, and efficiency is not just a dream; it is the potential reality that awaits those ready to innovate.