Maximizing Business Success with China Rapid Prototypes Factory

In today's competitive market, businesses are constantly seeking ways to innovate, reduce costs, and improve efficiency. One approach that has gained significant traction is the utilization of rapid prototyping services offered by factories in China. By leveraging these advanced manufacturing techniques, companies can streamline product development and enhance quality to stay ahead in their respective industries.

Understanding Rapid Prototyping

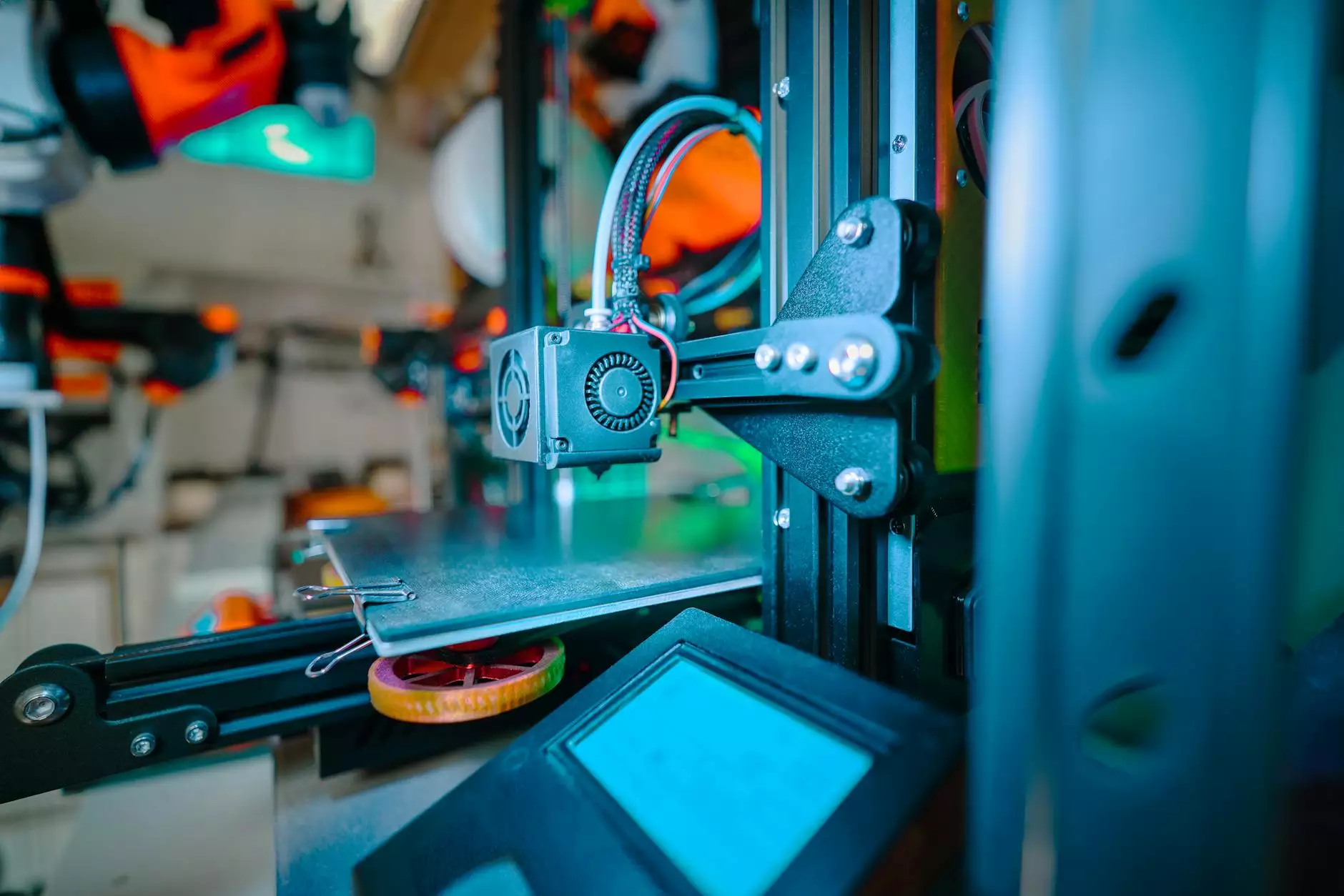

Rapid prototyping refers to a group of techniques used to quickly create a scale model of a physical part or assembly using 3D computer-aided design (CAD) data. This process allows for the immediate feedback needed to identify design flaws or modifications early in the development stage, ultimately reducing time-to-market and development costs.

The Benefits of Choosing a China Rapid Prototypes Factory

Cost Efficiency

One of the primary advantages of opting for a China rapid prototypes factory is the cost efficiency. Chinese manufacturers offer lower labor and material costs compared to their Western counterparts. This translates into significant savings for businesses looking to develop prototypes without compromising on quality.

Advanced Technology and Expertise

China has made remarkable advancements in manufacturing technologies, including 3D printing, CNC machining, and injection molding. A reputable rapid prototypes factory in China typically utilizes state-of-the-art machinery and employs skilled engineers who are proficient in the latest manufacturing techniques. This combination of technology and expertise ensures that the prototypes are produced with high precision and quality.

Faster Time-to-Market

Rapid prototyping is designed to expedite the product development cycle. By working with a China rapid prototypes factory, businesses can significantly reduce lead times. The ability to iterate quickly allows companies to test multiple designs, gather feedback, and make necessary adjustments before final production.

Key Services Provided by China Rapid Prototypes Factories

To maximize the benefits of rapid prototyping, it is essential to understand the various services that a China rapid prototypes factory offers:

- 3D Printing: A versatile manufacturing process allowing for complex designs and quick modifications.

- CNC Machining: A highly precise method ideal for producing functional prototypes with exact specifications.

- Injection Molding: Suitable for creating high-volume parts; it provides excellent finish and detail.

- Sheet Metal Fabrication: Effective for prototypes that require metal components, offering great durability and strength.

- Assembly and Finishing: Some factories provide assembly services, allowing businesses to receive a complete prototype ready for testing.

Choosing the Right Rapid Prototypes Factory in China

Finding the right China rapid prototypes factory can be a daunting task, but knowing what to look for can simplify the process. Here are essential factors to consider:

Expertise and Capabilities

Evaluate the factory’s experience and technical capabilities. A factory with extensive experience and a wide range of technologies can better accommodate diverse prototyping needs.

Quality Assurance

Look for factories that have a strong quality management system. Certifications such as ISO 9001 can indicate a commitment to quality.

Communication and Support

Effective communication is critical in the prototyping process. Ensure that the factory provides dedicated support and is responsive to inquiries and feedback.

Sample Work and References

Request samples of previous work or client references. This will give you insight into their capabilities and the quality of their output.

Case Study: Success with a China Rapid Prototypes Factory

Many companies have successfully utilized China rapid prototypes factories to enhance their product development cycle. For instance, a leading consumer electronics firm faced challenges in bringing a new device to market. By collaborating with a Chinese rapid prototyping manufacturer, they were able to:

- Reduce development time by 30%.

- Achieve a significant reduction in prototype testing costs.

- Iterate design based on real-time feedback effectively.

- Launch the final product two months ahead of schedule, gaining an edge over competitors.

This case demonstrates the tangible benefits of engaging with a high-quality rapid prototypes factory in China.

The Future of Rapid Prototyping in China

The future of rapid prototyping in China looks promising. With continued investments in technology, a focus on R&D, and an increasingly skilled workforce, Chinese factories are set to lead the industry globally. As trends shift towards customization, efficiency, and sustainability, rapid prototyping will play a crucial role in meeting these needs.

Conclusion

Engaging a China rapid prototypes factory can transform your product development process, enabling you to innovate faster and more cost-effectively. As businesses strive to enhance quality and reduce time-to-market, the role of rapid prototyping becomes more vital. When executed effectively, this approach not only fosters innovation but also lays the groundwork for sustainable success in the future.

If you're considering enhancing your manufacturing processes, Deep Mould is your go-to destination for state-of-the-art rapid prototyping services and metal fabrication solutions. Visit our website at deepmould.net to learn more about how we can assist you in optimizing your product development.